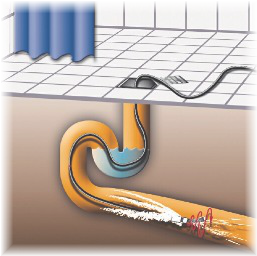

Es ist ein Albtraum jedes Haus- oder Wohnungsbesitzers: Der Abfluss ist verstopft, nichts laeuft mehr ab. Womoeglich laeuft die Toilette sogar ueber. Jetzt ist schnelle Hilfe gefragt, um die missliche Situation zu beseitigen und Folgeschaeden zu vermeiden: Unser Notdienst ist fuer Sie da, eine Rohrreinigung ist der einzige Weg.

Unsere Spezialgebiete sind neben der Kanalreinigung auch die Instandsetzung und Reinigung von Kanalnetzen. Wir sind fuer unsere Kundschaft im Einsatz, wenn es darum geht, verstopfte Abfluesse oder Abflussrohre zu reinigen und zu reparieren – im Notdienst und natuerlich bei geplanten Einsaetzen.

Sie benoetigen eine sofortige Abflussreinigung? Sie erreichen unseren Notdienst rund um die Uhr

Beim Thema verstopfter abfluss sind wir fuer Sie der richtige Ansprechpartner, Sie erreichen unseren Notdienst unter der kostenlosen Rufnummer 0800 8 666 667 rund um die Uhr, Tag und Nacht. Innerhalb von einer bis drei Stunden sind wir in ganz Nordrhein-Westfalen vor Ort – auch bei Ihnen!

Unsere Kundendienstfahrzeuge sind bei unseren Monteuren stationiert und mit einem GPS-System ausgestattet. So koennen die Einsaetze im Falle des Notdienstes vom Standort Solingen/Koeln aus EDV-gestuetzt koordiniert werden. Das spart im Notdienst Zeit, weil die Anfahrtswege zu den Einsatzorten auf diese Weise optimiert werden koennen.

Rohr dicht? Abfluss zu? Dann rufen Sie unseren Notdienst!

Die GreAt GbR Rohr- und Kanalreinigung bietet fuer alle Arbeiten rund um ihr Kanalnetz und Ihre Abflussrohre die erforderlichen Leistungen aus einer Hand. Das bedeutet: Wir sind nicht nur gefragte Spezialisten, wenn es um Rohrreinigung, Abflussreinigung oder Kanalreinigung geht. Wir kuemmern uns auch um den Rueckstauschutz, um den Austausch und Einbau von Bodeneinlaeufen und Senken sowie um den nachtraeglichen Einbau von Reinigungsoeffnungen in vorhandene Fallleitungen oder Revisionsschaechte. Wir kommen auch, um an Ihren Rohren Saug- und Pumparbeiten auszufuehren, Dichtheitspruefungen und Kanaluntersuchungen mit der Kamera vorzunehmen und schliesslich den Kanal zu sanieren.

Was kostet es, den Notdienst zu bestellen? Fragen Sie uns an, wir bieten Abflussreinigung zu fairen Preisen – auch im Notdienst. Wir berechnen eine

page1image19368

Anfahrtskostenpauschale von 16,50 € Tag und Nacht – egal, wo der Einsatzort in Nordrhein-Westfalen ist.